So you’ve got a cooler of some make and size, you want to use a CELR-12 to cook with it, but you want to make sure your cooler will work. One of the really cool things about the CELR-12 is that it can be used with any cooler, and its modular design is what allows it to be detached and stored when not in use. Because of this, each cooler that the CELR-12 is paired with will result in different performance. We test every cooler we can get our hands on and continually publish new tests on our site. This guide is to help us get on the same page regarding performance, and how to understand these tests. Before we get into the numbers, let’s start by defining what we can control, and what we will measure.

User Variables

When using the CELR-12, there are four variables you can control, these will affect how your machine to cooler pairing will perform.

- Contents

- This has an impact on speed and stability

- EXAMPLE If you put one can of beer in the cooler, it will cool down relatively quickly because it is small. If you instead put a case of beer in your cooler, it will take longer to cool down. However, the more massive the item in your cooler is, the more stable the temperature will be.

- Cooler size

- This primarily impacts how cold or hot your cooler can get, and how quickly it reaches your desired temperature

- A smaller cooler results in a wider differential window, and higher speed. As you increase the size of the cooler, these metrics will decrease.

- NOTE This variable is related to insulation, and assumes it is constant. A smaller, less insulated cooler may perform worse than a larger, better insulated cooler.

- Cooler insulation

- This primarily impacts how cold or hot your cooler can get, and how quickly it reaches your desired temperature

- Better insulation results in a wider differential window, and higher speed. As you decrease the insulation of the cooler, these metrics will decrease.

- NOTE This variable is related to size, and assumes it is constant. A smaller, less insulated cooler may perform better than a larger, better insulated cooler.

- Ambient air temperature

- This impacts your actual temperature range

- The CELR-12 works by creating a temperature differential inside your cooler from the ambient air temperature. This variable anchors your differential window, which is the number of degrees you can heat and cool your cooler.

- EXAMPLE If you have a potential differential of -50° F (this is information we provide in each test published to our site), but your ambient air temperature is 110° F, you will only be able to actually reach 60° F inside the cooler. If the ambient air temperature is 70° F, you’ll be able to reach 20° F inside the cooler with the same -50° F differential.

Performance metrics

Each combination of these four control variables will result in different values for our four performance metrics.

- Actual temperature range

- This takes into account your ambient air temperature and your differential window.

- EXAMPLE The CELR-12 paired with a certain cooler, used in 75° F ambient air temperature, can maintain temperatures between 20° F and 135° F inside the cooler (-55° F / +60° F is the differential window). If the ambient air temperature was 85° F, the differential window remains the same, but the actual temperature range would shift up ten degrees to 30° F and 145° F because the ambient air temperature shifted up ten degrees.

- Differential window

- This is a measure of how far from ambient air temperature you can heat or cool a specific cooler.

- EXAMPLE The CELR-12 paired with a certain cooler, can decrease temperature 55° F and increase 60° F inside the cooler from the ambient air temperature. (-55° F / +60° F)

- Speed

- This is a measure of how quickly you can heat or cool your cooler a certain amount.

- EXAMPLE The CELR-12 paired with a certain cooler, can decrease the temperature inside your cooler by 30° F below the ambient air temperature in 25 minutes.

- Stability

- This is a measure of how stable temperature is around a certain set point.

- EXAMPLE The CELR-12 paired with a certain cooler, can maintain temperature +/- 2° F around your set point, inside the cooler.

Understanding the tests

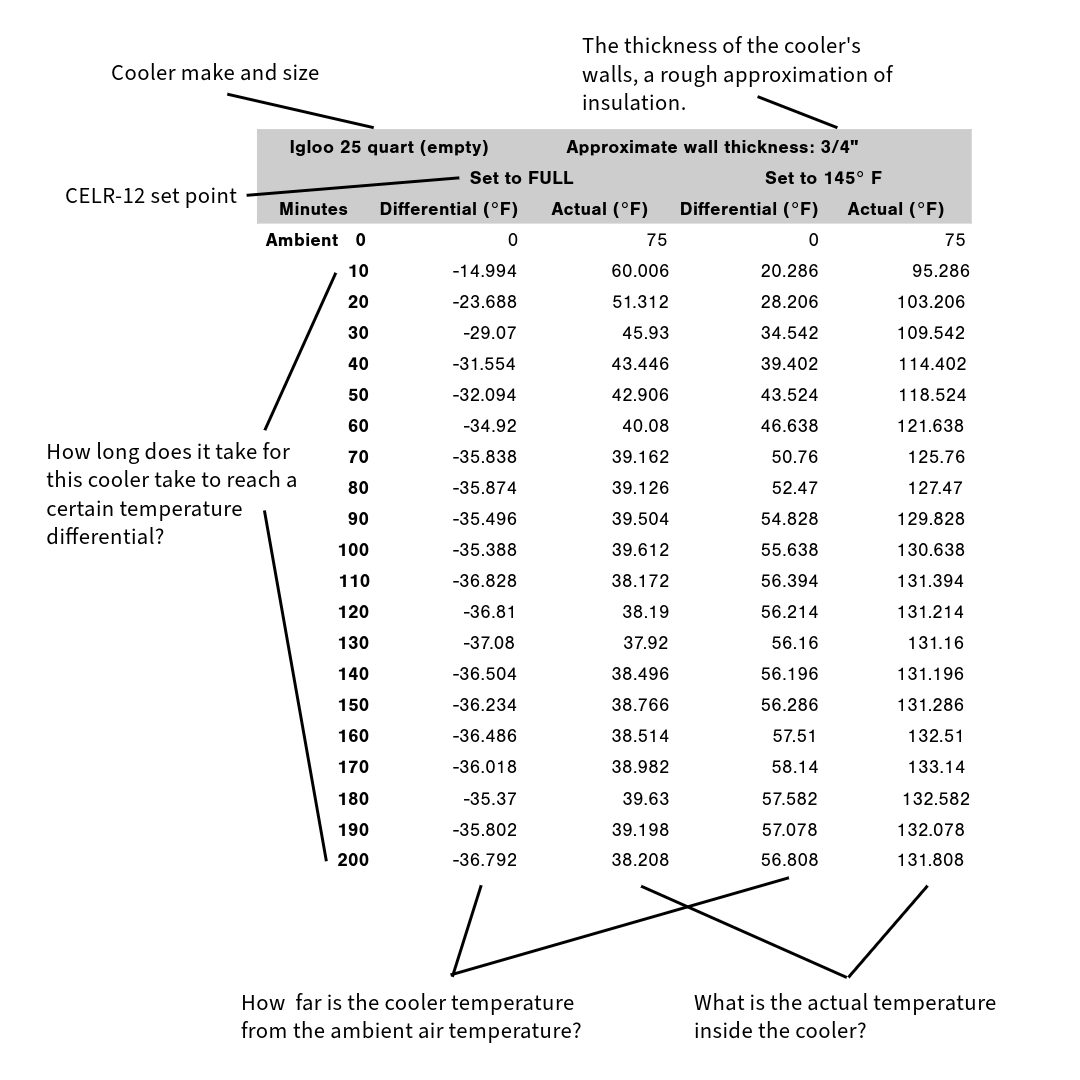

Now that we are speaking the same language, let’s get into the test data. Below is a diagram of what you will see in each test.

In addition to this, each test includes a graph which reflects this data, as well as runs at different set points, which demonstrate stability. All of our tests are conducted at about 75° F ambient air temperature with an empty cooler. Finally, each test includes a photo of the cooler being tested. Some manufacturers have different models of cooler that are the same size, but differ in insulation level. The photo is included to prevent any confusion in these cases. Ultimately, if you have any questions that can’t be answered by the tests, feel free to email me at marshall@tablesmith.us, I’m happy to help!